-

Aluminum Color Steel Sheet

-

Galvanized Color Steel Sheet

-

Ultra-high Weather Resistance

scroll down

SY produces

only high functional ceramic color steel sheets.

Compared to existing general RMP color steel sheet, ceramic color steel sheet is a state-of-the-art material that maintains its luster without discoloration over time due to its excellent weather resistance and corrosion resistance. In addition, it has non-staining properties and self-cleaning power to maintain cleanliness for a long time.

Having accumulated various application methods and manufacturing technologies as the Korea ‘s largest use of color steel sheets for nearly 30 years, SY combines its own color steel sheet technology and years of

R&D capabilities to manufacture and sell excellent ceramic color steel

sheets at almost the same price as general RMP color steel sheets.

As Asia's No. 1 sandwich panel company, SY is a true color

steel sheet manufacturing company equipped with

400,000 tons of color steel sheet production facilities

per year for its own use and domestic and foreign exports.

We will present a new paradigm for color steel sheets for

building materials by collaborating with world-class paint

companies such as PPG and VALSPAR to release products with a 40-year warranty.

-

Aluminum Color Steel Sheet

-

Galvanized Color Steel Sheet

-

Ultra-high Weather Resistance

- Excellent weatherability

No discoloration - Convenient cleaning

Easy to clean - Excellent stain resistance

No stain - Excellent machinability

No deformation

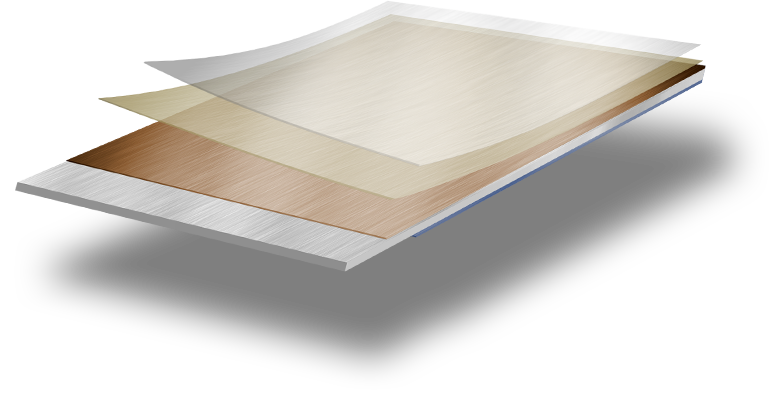

The secret of various colors,

convenient processability, high cleaning power

and weather resistance is SY's unique

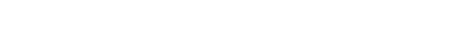

ceramic color coating system.

ⓒ SY Ceramic Color COATING SYSTEM

SY's ceramic technology presents

a new standard for color steel sheets.

Comparison of color steel sheet performance by type

- General RMP

- Fluorine Coating(PVDF)

- Main material

- GI / AL

- GI / AL

- Color diversity

- ★★★

- ★

- Gloss maintenance

- ★

- ★★★

- Weather resistance

- ★

- ★★★

- Economical efficiency

- ★★★

- ★

- Machinability

- ★★★

- ★★★

- Stain resistance

- ★

- ★

- Cleaning power

- ★

- ★

- Pure Ceramic

- Ceramic Hyperville

- Hyperville40

- AL

- GI

- GI / AL

- ★★★

- ★★★

- ★

- ★★

- ★★

- ★★★

- ★★

- ★★

- ★★★☆

- ★★★

- ★★★

- ★★

- ★★★

- ★★★

- ★★★

- ★★★

- ★★★

- ★★

- ★★★

- ★★★

- ★★

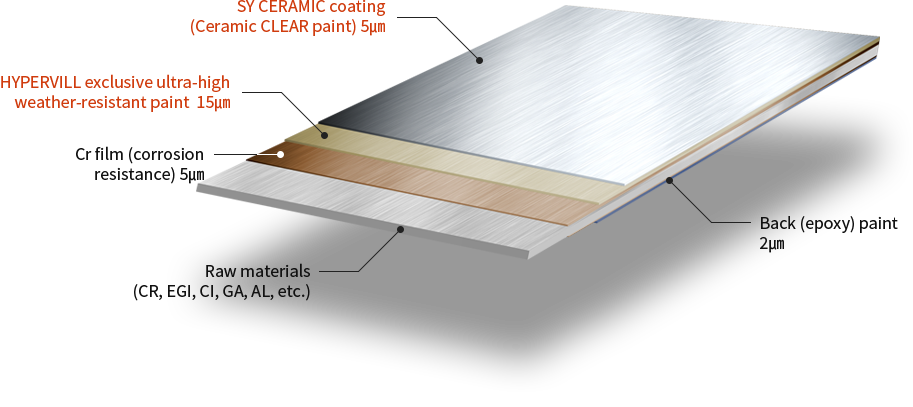

Color steel sheets exposed to the outside for a long time may undergo deformation such as discoloration, gloss loss, and chalking over time. Ceramic color steel sheet is noteasily discolored due to its good weather resistance.

External

contamination case

Discoloration case

Chalking

It is clean

when coated with color steel plate and ceramic.

Non-pollution durability is good.

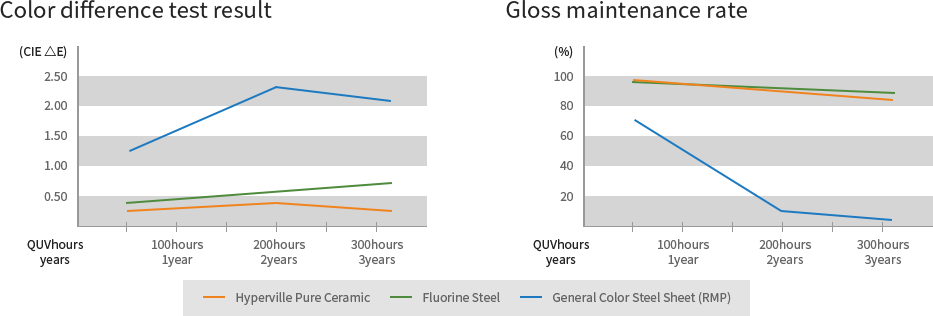

Since color steel sheet is used as a product that is continuously exposed to the external environment, such as building exterior materials, there is a high possibility of contamination due to UV rays and pollutants in the air left unattended for a long time. Existing RMP color steel sheets often degraded the aesthetics and lowered the value of the building due to the aging of the painted surface or the adhesion of contaminants such as soil, dust, yellow sand, exhaust gas, and tire powder.

Having non-polluting properties that fundamentally block the source of contamination on the surface of the steel sheet, SY ceramic color steel sheet maintains a clean surface for a long time because adhering contaminants are washed away when it rains.

ⓒ Principle of SY Ceramic Color Self-cleaning power

Ceramic coating treatment prevents contaminants in the air from

adhering to the surface of the product. Hanging contaminants are

also easily cleaned with water.

Use SY Ceramic Color Steel Sheet.

The value of buildings goes up,

and cleaning costs are saved.

ⓒ Comparison of exterior cleaning costs for buildings based on 10,000㎡ (20 years)

<1.26 billion won>

- After the 3rd year of construction

- Cleaning once a year

- Cleaning fee: KRW 7,000 per ㎡

Buildings with general color

steel plate (RMP) applied

<630 million won >

- Cleaning once

every 2 years

Building with SY ceramic

color steel plate applied

Ft. Myers Outdoor Test completed

In collaboration with world-class paint companies such as PPG and VALSPA, SY produces color steel sheets with excellent resistance to coating film damage caused by UV rays such as discoloration, gloss loss, and chalking.

Fort Myers is a city in the southern tip of Florida, USA. It is a city optimized for weather resistance tests due to the large amount of sunlight throughout the year. SY makes high functional ceramic color steel sheets combined with our ceramic coating technology using only paints that have been verified through the Fort Myers outdoor exposure test for many years.

Worldwide No.1 ultra-high

weather-resistance color steel sheet.Guarantees quality for up to 40 years.

Hyperville 40 is a color steel plate with a 40-year warranty in collaboration with world-class paint companies such as PPG and VALSPA. If you need a semi-permanent product with ultra-high weather resistance, we recommend Hyperville 40.

Items and Details of Hyperville 40 Warranty

| Material perforation | Surface cracks and peeling | Bleaching and discoloration | Choking | |

|---|---|---|---|---|

| Roofing material | 40 years | 30 years | ≤△E 10 (30 years) |

≥#4 (30 years) |

| Wall | 40 years | 30 years | ≤△E 8 (30 years) |

≥#6 (30 years) |

※ Within 1km of coastal and industrial areas are excluded from warranty.

※ For details, please check the full warranty issued at the time of purchase.

SY produces aluminum color steel sheets

and galvanized color steel sheets

in Korea, Vietnam and Cambodia.

SY’s CCL holding status and manufacturing scope

-

CCL Phase 2

CCL Phase 2Korea

-

CCL Phase 2

CCL Phase 2Vietnam

-

CCL Phase 1

CCL Phase 1Cambodia

- GI

- Thickness 0.23 ~ 1.6mmWidth 600 ~ 1600mm

- AL

- Thickness 0.3 ~ 2.2mmWidth 600 ~ 1710mm

- Person

in charge - Steel Team 070-4808-0625Quality Team 070-4808-1146Export Team 070-4808-1729

SY Ceramic contains

All colors in the world.

Pure Ceramic and Ceramic Hyperville incorporate SY's unique ceramic coating technology

to express various colors while maintaining high functionality such as weather resistance,

non-staining properties, and workability.

It retains the luster without discoloration for a long time with a soft color, and adds luxuriousness.

It can be applied in various forms due to

its excellent processability.

- Panels for building exteriors

- Roofing materials

- Walls

- Composite panels

- Exterior materials

- Interior materials

- Partition

- Fire door

- Signage

- Refrigerator

- Washing machine

- Gas stove

- Others

Technical Summary

Features and Characteristics of Resin

| Conventional RMP panel | Hyperville Ceramic Panel | |||

|---|---|---|---|---|

| Resin Type | Mw | 8,000 ~ 10,000 | 20,000 ~ 25,000 | |

| OH v | 20 ~ 30 | 15 ~ 20 | ||

| Tg | 10 ~ 20℃ | 30 ~ 40℃ | ||

| Curing System | Melamine / Acid catalyst | Melamine / Acid catalyst Some Isocyanate applied |

||

| Anti Corrosion additive | x | Silica type rust inhibitor applied | ||

| Adhesive promoter | x | Phosphoric acid type | ||

Superiority of Ceramic Hyperville Panel

| TEST ITEMS | TEST METHOD | SPEC | Hyperville panel | Conventional RMP panel |

|---|---|---|---|---|

| Gloss | 60 degree gloss | - | 30 ~ 35% | 25 ~ 30% |

| BASE | - | Ivory, silver gray, blue, etc. | 15 ~ 5㎛ | 5 ~ 15㎛ |

| Pencil hardness | Mitsubishi-pencil | F or more | H ~ 2H | H ~ 2H |

| Erichsen Test | 100x100x6mm, Taping | There should be no peeling of the coating film. | Excellent | Good |

| Impact | 1/2"(ballsize)x500g(load)x50cm(height) | There should be no peeling of the coating film. | Excellent | Good |

| Machinability | T-Bending, taping | 2T 4 points | 1T 4 points | 2T 4 points |

| Degree of hardening | MEK Rubbing(50 times) | There should be no peeling or traces of the coating film. | Excellent | Good |

| Warranty period | Usually 5 year | 7 years | 5 years | |

| Chemical resistance | 5% HCl x 24hrs, 5% NaOH x 24hrs | There should be no problem. | Excellent | Good |

| Stain resistance | Carbon test | Should be erased easily. | Easily erased | Heavily stained |

| Boiling water resistance | 98℃ x 1hr | There shall be no peeling of the coating film and no discoloration. | Excellent | Good |

| Eraseness | Magic test | Black, Blue, Red permanent marker | Easily erased | Traces left |

| Corrosion resistance | X-cut, flat part | 240hrs / 500hrs | Excellent / Excellent | Good / Good |

| Weather resistance | W-O-M (500 hours) | dE / Gloss maintenance rate | 0.27 / 103% | 0.39 / 93% |

| QUV-B (500 hours) | dE / Gloss maintenance rate | 0.31 / 103% | 0.38 / 44% |