Deck Plate

Innovative method according to market change

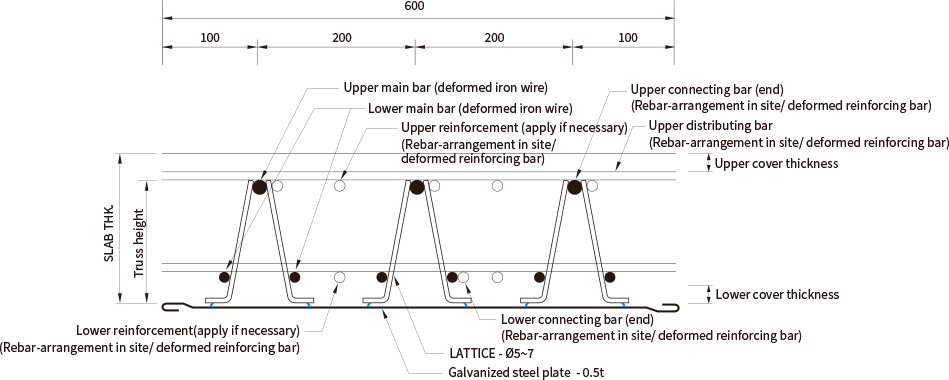

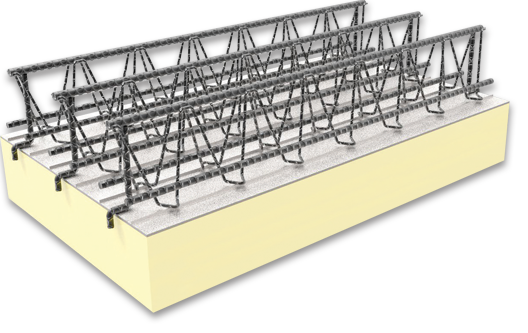

The deck plate produced and supplied by SY Steeltech is a product in which a truss girder is assembled with deformed iron wire with high yield strength instead of a plywood mold when constructing a building floor slab, and the truss girder is integrated with electric welding on a 0.5mm thick galvanized steel sheet. It is a moldless, non-boiling slab construction method.

Product Inquiries 070-4659-4647

Product Inquiries 070-4659-6293

- Product Information

- Construction order

-

TG-deck

-

TG-DECK welding point non-exposed type

By forming the RIB of the steel plate, the truss and the steel plate are perfectly integrated through direct welding.

It prevents corrosion of steel plate because the lower welding point of the existing one-piece deck is not exposed, and the finish is beautiful. It is an excellent product in terms of stability as it is easy to control with PITCH automation in the production line.Constituent materials

LATTICE : Ø5~Ø7 DECK PLATE : 0.5T galvanized steel plate (KS-SGC 400) TG TYPE SIZE : 600mm×1,200~5,500mm (W×L) Applicable slab THK : 120mm~300mm PITCH : 200mm

TYPE Upper rail Lower rail TG15 D10-1 D8-2 TG25 D10-1 D10-2 TG35 D13-1 D8-2 TG45 D13-1 D10-2 TG55 D13-1 D13-2 TG65 D10-1 D7-2 TG75 D12-1 D7-2 TG85 D12-1 D8-2 TG95 D12-1 D10-2 TG105 D14-1 D10-2 TG115 D13-1 D7-2 TG125 D14-1 D12-2 TG135 D13-1 D12-2 Remarks Ø5 LATTICE TYPE Upper rail Lower rail TG16 D10-1 D8-2 TG26 D10-1 D10-2 TG36 D13-1 D8-2 TG46 D13-1 D10-2 TG56 D13-1 D13-2 TG66 D10-1 D7-2 TG76 D12-1 D7-2 TG86 D12-1 D8-2 TG96 D12-1 D10-2 TG106 D14-1 D10-2 TG116 D13-1 D7-2 TG126 D14-1 D12-2 TG136 D13-1 12-2 Remarks Ø6 LATTICE -

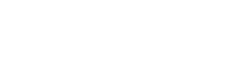

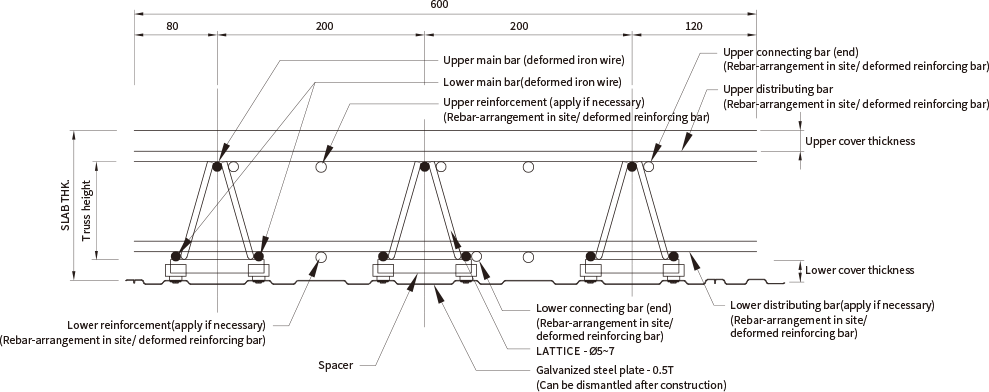

Green deck

-

Before steel plate separation

Before steel plate separation

After steel plate separation

After steel plate separation

Steel plate demolding method possible after construction by bolting joint between triangular truss and galvanized steel plate.

An innovative eco-friendly product that can be recycled and immediately cope with cracks and leaks by separating and demolding the lower steel plate after concrete curing.

Integration of truss girder and galvanized steel sheet by bolting connection. Immediate response to cracks and leaks after concrete curing to minimize damage. An eco-friendly product since demolded steel sheet can be reused.Constituent materials

LATTICE : Ø5~Ø7 DECK PLATE : 0.5T galvanized steel plate (KS-SGC 570) TG TYPE SIZE : 600mm×1,200~5,500mm (W×L) Applicable slab THK : 120mm~300mm SPACER PITCH : 400mm

TYPE Upper rail Lower rail G15 D10-1 D8-2 G25 D10-1 D10-2 G35 D13-1 D8-2 G45 D13-1 D10-2 G55 D13-1 D13-2 G65 D10-1 D7-2 G75 D12-1 D7-2 G85 D12-1 D8-2 G95 D12-1 D10-2 G105 D14-1 D10-2 G115 D13-1 D7-2 G125 D14-1 D12-2 G135 D13-1 D12-2 Remarks Ø5 LATTICE TYPE Upper rail Lower rail G16 D10-1 D8-2 G26 D10-1 D10-2 G36 D13-1 D8-2 G46 D13-1 D10-2 G56 D13-1 D13-2 G66 D10-1 D7-2 G76 D12-1 D7-2 G86 D12-1 D8-2 G96 D12-1 D10-2 G106 D14-1 D10-2 G116 D13-1 D7-2 G126 D14-1 D12-2 G136 D13-1 D12-2 Remarks Ø6 LATTICE -

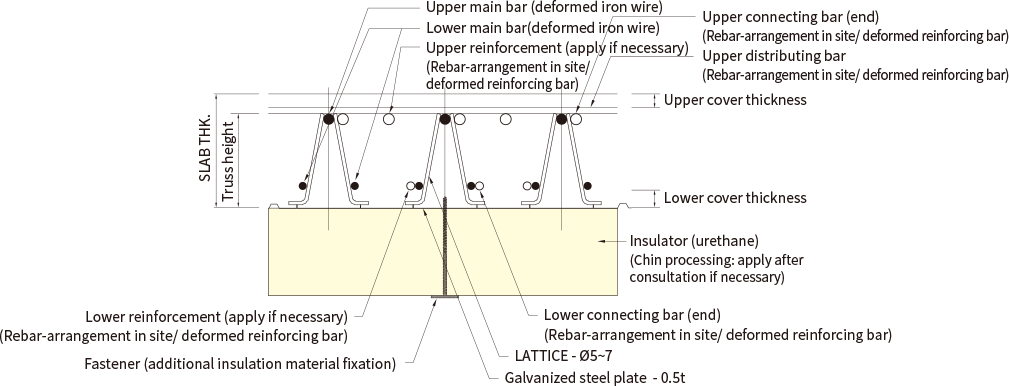

Heat deck

-

Innovative method according to market change.

HEAT DECK is a new product produced by attaching a urethane insulation material with excellent thermal insulation to the lower part of the deck plate, a step forward from the existing method of constructing the deck plate first and then additionally installing the insulation under the deck plate. The construction becomes simpler, the construction period is shortened, and the insulation performance is doubled as there are no gaps.

Shortened construction period by omitting the insulation process and excellent insulation performance (energy saving effect) through seamless construction. Reduced construction cost compared to construction after insulation.Constituent materials

LATTICE : Ø5~Ø7 DECK PLATE : 0.5T galvanized steel plate (KS-SGC 400) TG TYPE SIZE : 600mm×1,200~5,500mm (W×L)Purpose of use

Reinforced concrete (RC) Steel frame (S) Steel Reinforced Concrete (SRC)Production thickness (based on deck)

Applicable slab THK : 120mm~300mm Insulation THK : 50mm ~ 200mm

TYPE Upper rail Lower rail H15 D10-1 D8-2 H25 D10-1 D10-2 H35 D13-1 D8-2 H45 D13-1 D10-2 H55 D13-1 D13-2 H65 D10-1 D7-2 H75 D12-1 D7-2 H85 D12-1 D8-2 H95 D12-1 D10-2 H105 D14-1 D10-2 H115 D13-1 D7-2 H125 D14-1 D12-2 H135 D13-1 D12-2 Remarks Ø5 LATTICE TYPE Upper rail Lower rail H16 D10-1 D8-2 H26 D10-1 D10-2 H36 D13-1 D8-2 H46 D13-1 D10-2 H56 D13-1 D13-2 H66 D10-1 D7-2 H76 D12-1 D7-2 H86 D12-1 D8-2 H96 D12-1 D10-2 H106 D14-1 D10-2 H116 D13-1 D7-2 H126 D14-1 D12-2 H136 D13-1 D12-2 Remarks Ø6 LATTICE

-

Steel frame construction order (S)

-

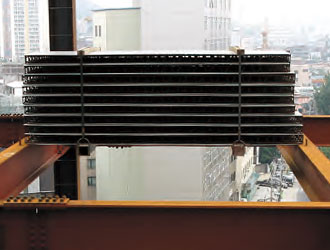

TG DECK products standardized through full automation of all processes use a new construction method that contributes to the improvement of construction quality by maintaining the exact spacing of the main rebar and coating thickness, and supplementing corrosion and paste leakage due to non-exposure of welding points. No slab molds or supporting posts are required when installing TG deck, shortening the construction period, reducing construction costs and maximizing the improvement of the construction environment.

01On-site warehousing

01On-site warehousing 02Lifting

02Lifting 03Stacking

03Stacking 04Plate opening

04Plate opening 05Stud Bolt welding

05Stud Bolt welding 06Stopper work

06Stopper work 07Reinforcement placing

07Reinforcement placing 08Electrical equipment

08Electrical equipment 09Concrete pouring

09Concrete pouring -

Construction order of steel frame concrete (RC)

-

TG DECK products standardized through full automation of all processes use a new construction method that contributes to the improvement of construction quality by maintaining the exact spacing of the main rebar and coating thickness, and supplementing corrosion and paste leakage due to non-exposure of welding points. No slab molds or supporting posts are required when installing TG DECK, shortening the construction period, reducing construction costs and maximizing the improvement of the construction environment. In particular, it is easy to secure a smooth working space in the lower part as no supporting post is required in the construction of reinforced concrete.

01On-site warehousing

01On-site warehousing 02Lifting

02Lifting 03Stacking

03Stacking 04Plate opening

04Plate opening 05Installation inspection and dimension measurement

05Installation inspection and dimension measurement 06Fixing bar

06Fixing bar 07Connecting bar, distributing bar

07Connecting bar, distributing bar 08Electrical equipment

08Electrical equipment 09Concrete pouring

09Concrete pouring -

Demolding construction order (S, RC)

-

GREEN DECK (demolding deck) is a method of bolting a truss girder and a lower steel plate to a spacer, removing the bolts after curing the concrete, and demolding the steel plate. It is a very effective method for maintenance when cracks and leaks occur due to the exposure of concrete surface.

01On-site warehousing

01On-site warehousing 02Lifting

02Lifting 03Stacking

03Stacking 04Plate opening work

04Plate opening work 05Plate opening completed

05Plate opening completed 06Reinforcement placing

06Reinforcement placing 07Pouring

07Pouring 08Demolding work

08Demolding work 09Demolding completed

09Demolding completed -

Insulation construction order (S, RC)

-

HEAT DECK (insulated deck) is an integrated flooring material produced by attaching a urethane insulation material with excellent thermal insulation to the lower part of the deck plate. The simplification of the process shortens the construction period and reduces construction costs. It is also a construction method that can simplify subsequent processes. It has excellent adhesion strength due to the insulating material bonding method, and factory automation enables mass production.

01On-site warehousing

01On-site warehousing 02Lifting

02Lifting 03Stacking

03Stacking 04Plate opening

04Plate opening 05End fixation

05End fixation 06Plate opening completed

06Plate opening completed 07Reinforcement placing

07Reinforcement placing 08Pouring

08Pouring 09Installation complete (bottom)

09Installation complete (bottom)

Korean

Korean English

English